Imagine your frozen salmon fillets surviving a 5-day journey from Alaska to Dubai—through deserts, customs delays, and clumsy forklift drivers. The secret weapon? A perfectly choreographed tango between stretch film supplies and thermal insulation. Let’s break down this cold chain power couple and how RXPACK’s tech turns logistical nightmares into frosty victories.

Why Cold Chain Packaging Isn’t Just “Keep It Cold”

Spoiler alert: Ice packs alone won’t cut it. The FDA reports 12% of temperature-sensitive shipments arrive compromised. Here’s what really matters:

1. The Deadly Trio: Temperature Swings, Condensation & Physical Abuse

Real-World Nightmare: A Miami-bound vaccine pallet hit with:

- 🌡️ 72°F warehouse delays

RXPACK Fix: Nano-coated stretch film + Aerogel panels = -20°C stability with drop protection.

2. The Physics of Cold: It’s Not Just About Chill

Conduction vs Convection vs Radiation

Your insulation battles heat transfer three ways—like fighting zombies with a shotgun, flamethrower, and laser sword simultaneously:

- ❄️ Conduction: RXPACK’s ceramic-infused films block surface heat transfer

The Dynamic Duo: Stretch Film & Insulation in Action

Think Batman (film) and Robin (insulation)—separately good, together unstoppable.

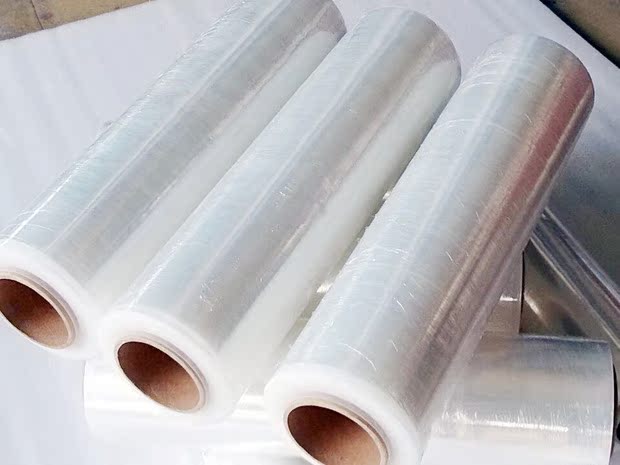

3. Pre-Stretched Film: The Invisible Force Field

RXPACK’s Pre-Stretched film does triple duty:

Cold Chain Hacks: Real Companies Winning the Frost Game

4. The Sushi Savior: From Tokyo to Texas

A premium seafood co. switched to RXPACK’s CryoWrap system:

5. Flower Power: Roses That Survived a Heatwave

Kenyan rose farm’s solution:

Future-Proofing: The Cold Chain Arms Race

What’s next in the frosty frontier?

6. Smart Films That Text You When They’re Struggling

RXPACK’s prototype films with embedded sensors:

Conclusion: Cold Chain Success = Physics + Grit

Mastering cold logistics isn’t about throwing money at problems—it’s about strategic alliances between stretch film supplies and smart insulation. With RXPACK as your wingman, you’ll turn temperature tantrums into frosty high-fives.

FAQs

1. How thick should cold chain stretch film be?

80-120 gauge (20-30µ). Thinner films risk tears; thicker reduces stretch.

2. Can I reuse insulation panels?

Vacuum panels: 3-5 uses. RXPACK’s aerogel: 50+ cycles if undamaged.

3. What’s the biggest cold chain killer?

Temperature fluctuations > sustained heat. Use phase-change materials!

4. How to prevent condensation?

Desiccants + vapor-proof stretch film wrapping. Our DryArmor films block 99.9% moisture.

5. Are RXPACK solutions FDA-compliant?

All materials meet FDA 21 CFR for food/pharma contact. Audit-ready documentation included!