Ever watched a colleague wrestle with a tape dispenser like it’s an angry octopus? You’re not alone. At RXPACK, we’ve seen every loading mistake imaginable – including the infamous “tape mummy” incident. Let’s turn you into a tape-loading ninja with manufacturer-approved techniques.

The Anatomy of a Tape Dispenser: Know Your Weapon

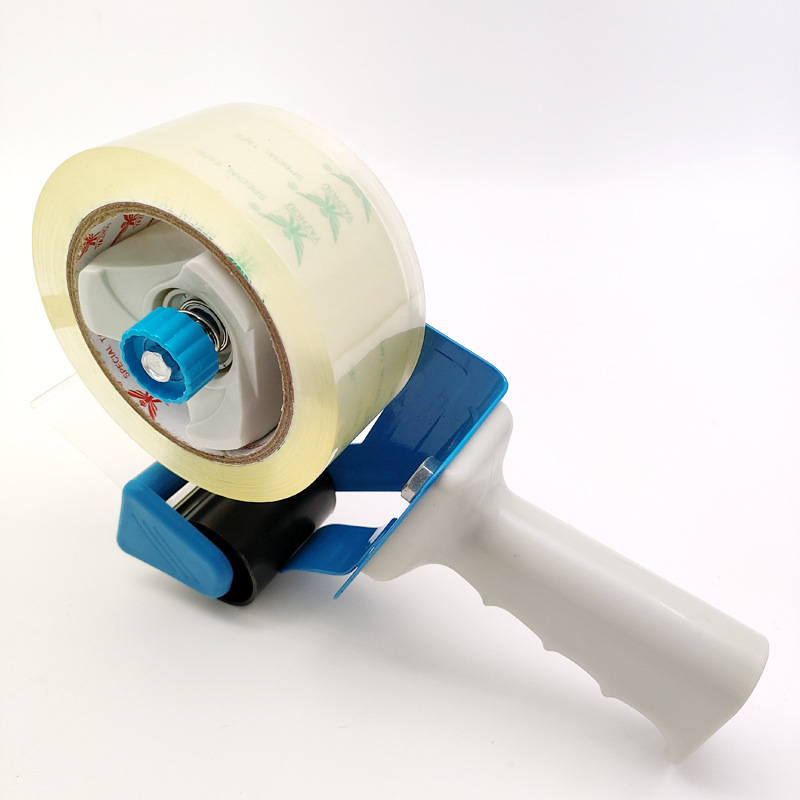

Before loading your RXPACK ProDispenser, understand its parts:

- 🔪 Cutting blade (the hungry shark)

- 🌀 Tape roll spindle (the heart)

- ⚖️ Tension arm (the unsung hero)

Step 1: The Manufacturer-Approved Unboxing

Don’t Just Rip It Open!

90% of first-time users damage dispensers during unboxing. Do this instead:

- 📦 Cut plastic wrap with scissors (never pull)

- 🔧 Remove transit locks (prevents tension damage)

- 🧹 Wipe down with dry cloth (removes factory dust)

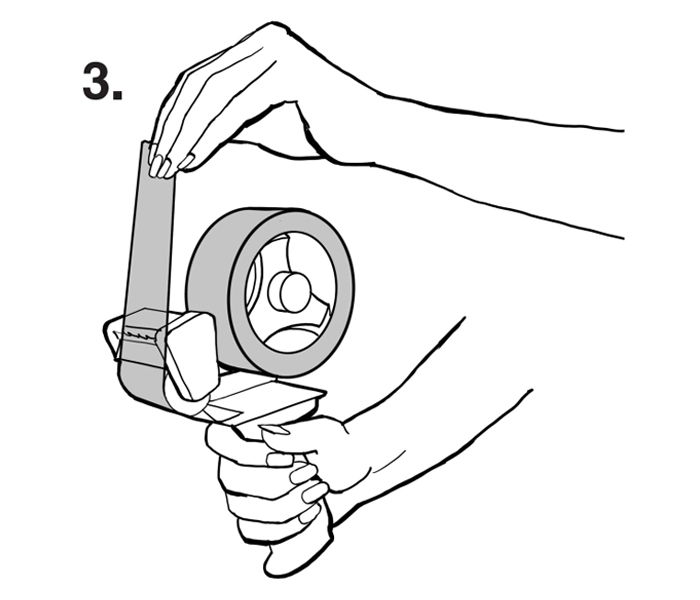

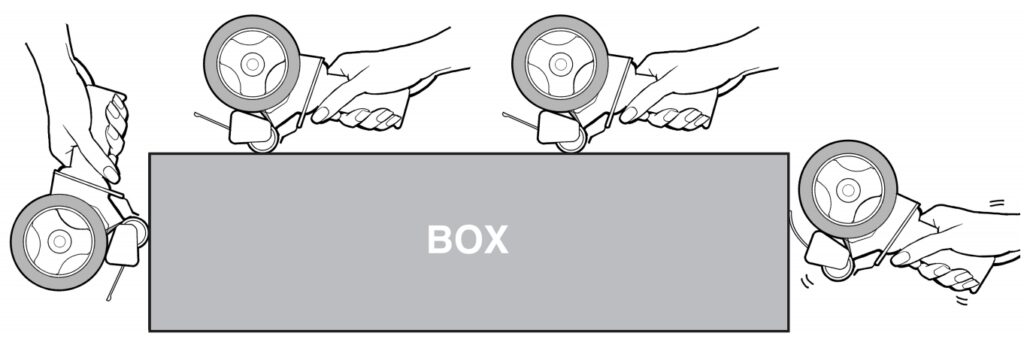

The 5-Second Loading Technique Used in Warehouses

RXPACK’s factory teams load 500+ dispensers daily. Here’s their secret:

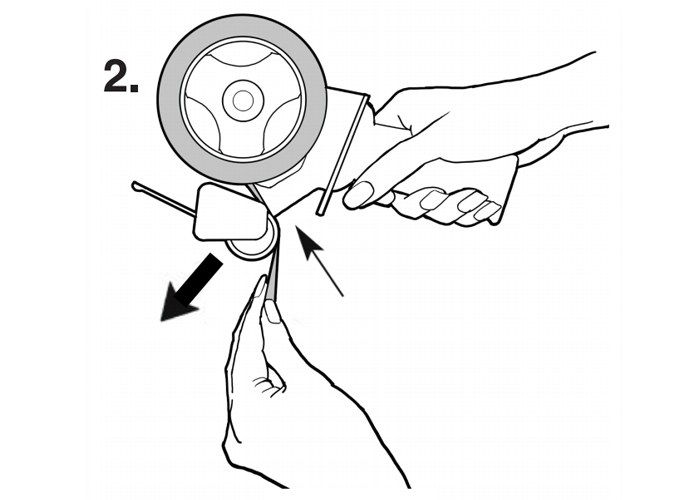

Step 2: Tape Orientation Matters

| Tape Type | Correct Direction |

|---|---|

| Standard Acrylic | Adhesive side down |

| Water-Activated | Non-gummed side up |

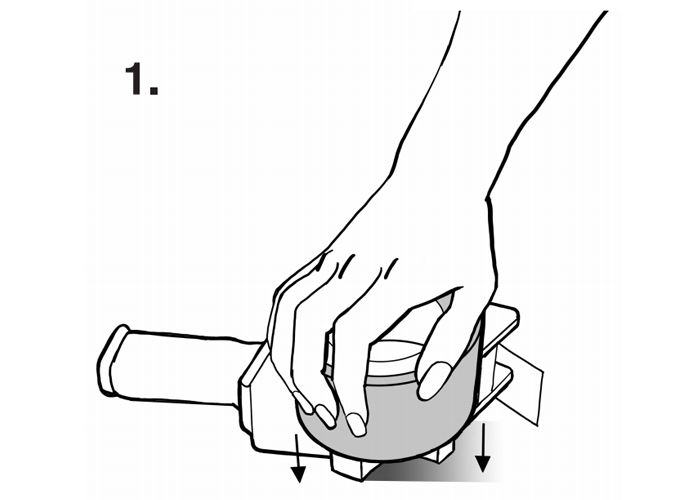

Step 3: The Tension Tango

Too tight = tape breaks. Too loose = spaghetti mess. Goldilocks technique:

- 👉 Push tension arm to 45° angle

- 👂 Listen for 1 click (not 3!)

- 🔄 Test by pulling 12″ tape – should unspool smoothly

5 Loading Mistakes That Cost Companies $18k/Year

Mistake 1: Ignoring Core Direction

Using our DirectionCheck Dispensers solves:

- 🌀 Anti-clockwise vs clockwise confusion

- ⏱️ 22-second average time saved per load

Mistake 2: Overlooking Blade Alignment

Crooked blades = jagged cuts. Fix with:

- 📏 RXPACK’s LaserAlign™ system

- ⚙️ Monthly 2-minute calibration

Pro Maintenance: Keep Your Dispenser Singing

Treat it like a Stradivarius violin:

- 🧼 Weekly alcohol wipe-downs (prevents adhesive buildup)

- 🔧 Quarterly tension spring checks

- 🔄 Annual full rebuild with Maintenance Kits

Case Study: E-Commerce Giant Saves 1,200 Hours/Year

After training staff with RXPACK’s loading protocol:

- ⏱️ 78% faster loading times

Choosing Your Dispenser: Not All Heroes Wear Capes

Match tools to your tape type:

- 📦 Light-duty: Manual tabletop models

Conclusion: Loading Mastery = Productivity Gold

Proper dispenser loading isn’t just about tape – it’s about respecting the engineering behind packing tape manufacturer tools. Master these steps, and you’ll be the warehouse wizard everyone asks for help!

FAQs

1. Why does tape curl after loading?

Wrong core direction! Flip the roll and retension.

2. How often to replace blades?

Every 50 rolls or when cuts feel “crunchy”.

3. Can I use any brand tape?

Stick to manufacturer-recommended tapes for warranty.

4. Safe cleaning solutions?

70% isopropyl alcohol only. Never use water!

5. Dispenser making weird noises?

Likely spring tension issues. Time for maintenance!